This pipe bender uses the formed pipe bending tool to directly cold-bend the pipe fittings of corresponding specifications, without heating and sanding means, and is easy to operate. It is a necessary hydraulic machine tool for pipe fitting installation and maintenance operations.

WGQ-10 pipe bender is used together with LL45/250LL oil cylinder and SYB-1 manual pump or DYB-1A electric oil pump. Used to bend steel pipes and steel bars.

Description

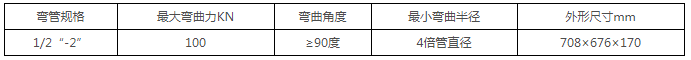

1. Specifications:

(1) Elbow specification (water gas pipe) 1/2"~2"

(2) Specification of bent steel bar (45 steel) section ≤ Φ38mm

(3) Bending force 10t

(4) Bending angle ≥ 90°

(5) Dimensions (length × width × height) 708 × 676 × 170mm

2. Parts and components list

(1) 1 set of rack body

(2) 1 set of outer bracket and fixing screw

(3) 1 head

(4) Bend tube tires (1"/2, 3"/4, 1", 5"/4, 3"/2, 2") 6 pieces

(5) Roller sleeve

(6) Shaft 2 sets

Accessories:

(1) Oil pump SYB-1 manual oil pump

(2) Oil cylinder LL45/250LL oil cylinder

Installation and use

(1) Remove the top cap and protective cover from the LL45/250LL oil cylinder, screw them on the two grooves of the frame body seat, screw the top head on the head of the oil cylinder, and put the bracket on the tail.

(2) Select the required bent tube tire and press it on the head.

(3) Use two shafts to install the two liquid wheels in the required holes of the support plate. Select the required groove on the roller so that it is opposite to the direction of the bent tube tire.

(4) Connect the oil cylinder to the oil pump, put the steel pipe to be bent between the pipe bending tire and the roller, and the pipe can be bent.

3. Working principle

The pipe bender is composed of a frame, a bending tire, and an oil pump. The oil cylinder is mounted on the frame through threads, and the bending tire is installed on the head of the cylinder piston. Rollers are installed on the frame, and the pipe to be bent is installed on the rollers. .

When the oil pump supplies pressure to the oil cylinder, the oil cylinder pushes the variable tube tire to press the pipe to be bent, and under the joint action of the pipe bend tire and the rollers, the pipe to be bent is bent into a required angle.

Matching parts are selected with SYB-1 type manual oil pump or DYB-1A type electric oil pump. Oil cylinder adopts LL45/250LL type.

Technical Parameters